Japanese Carpentry – Nokogiri 鋸

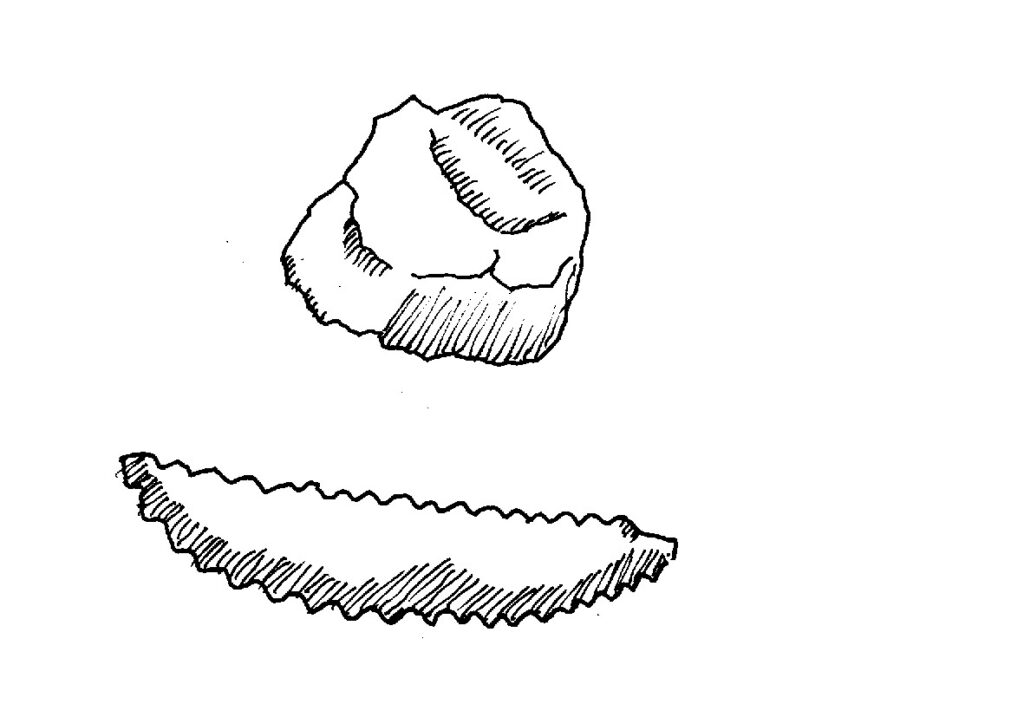

Since our first ancestors split a stone and used it to sharpen a stick, humans have been making and using tools.

Hammers, knives and axes can all be made with stone, bone or wood. Over time stone chipping techniques became more sophisticated, and serrated edges or teeth were found to be more effective at some cutting tasks, because the cutting edge was longer and at an angle to the cut.

The earliest known saws made of stone date to tens of thousands of years ago, and records exist of copper pull saws in Egypt from the 31st century B.C. The Egyptians went on to develop raked teeth and teeth “set” to project to the side of the blade. The sets make the saw cut very slightly wider than the blade, so there is less resistance.

Making saws remained complicated and expensive until the advent of steel manufacture, so for common work, such as building ships or houses, wedges were used to split wood along the grain and chisels or axes were used for cross-cutting and finishing.

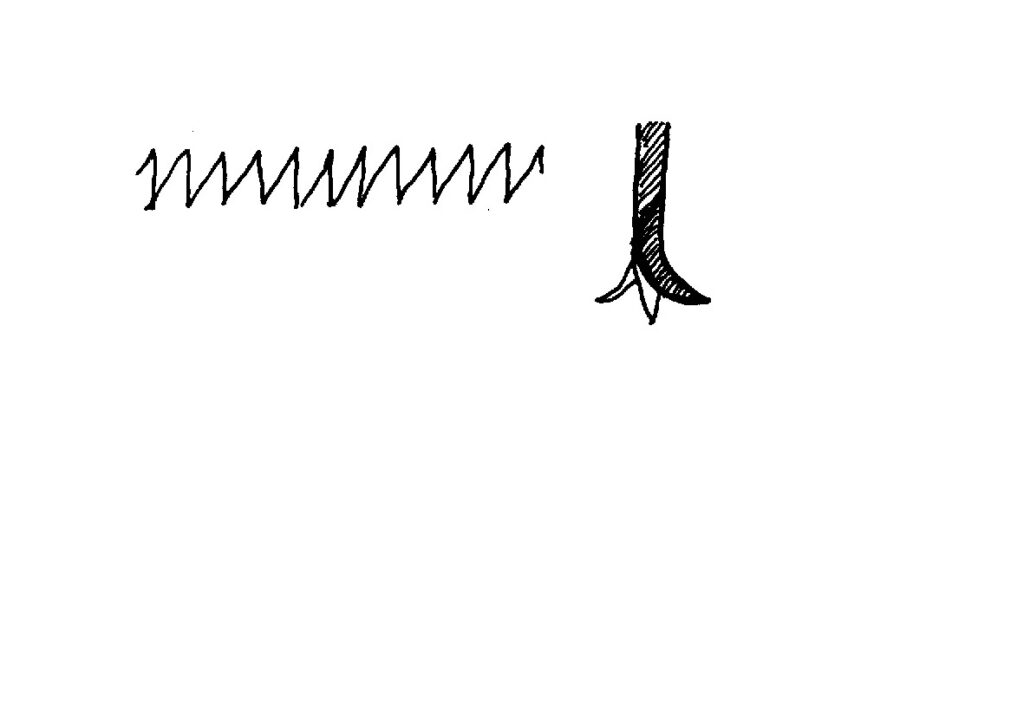

The saw as it developed in the west was a “push saw”, in which the woodworker stood and pushed the saw, using his body weight, to cut the wood.

In the east the Chinese developed the ‘pull saw”, and this type is used today across northern Asia, from Turkey to Japan.

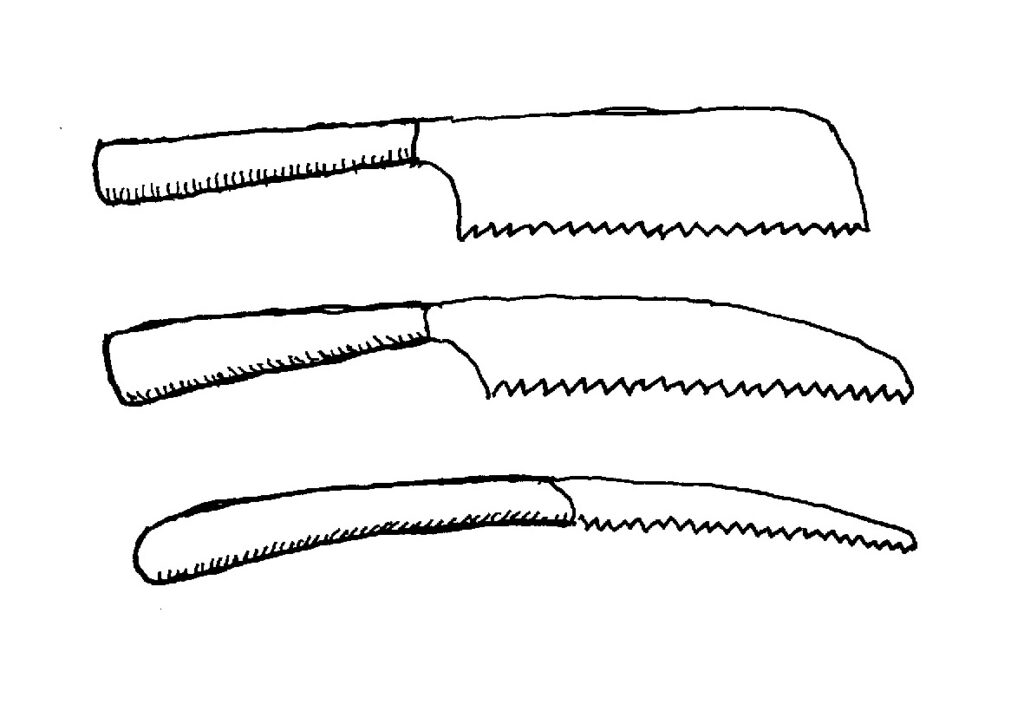

It is thought that the saw was brought to Japan during the Kofun period (300 – 500 AD). The earliest-known building constructed using saws is Horuji Temple in Nara, founded in 607, where concealed timber exhibits saw-cuts rather than axe-marks. A saw from this time was preserved in the temple. It has a straight blade with an in-line wooden handle similar to a serrated kitchen knife.

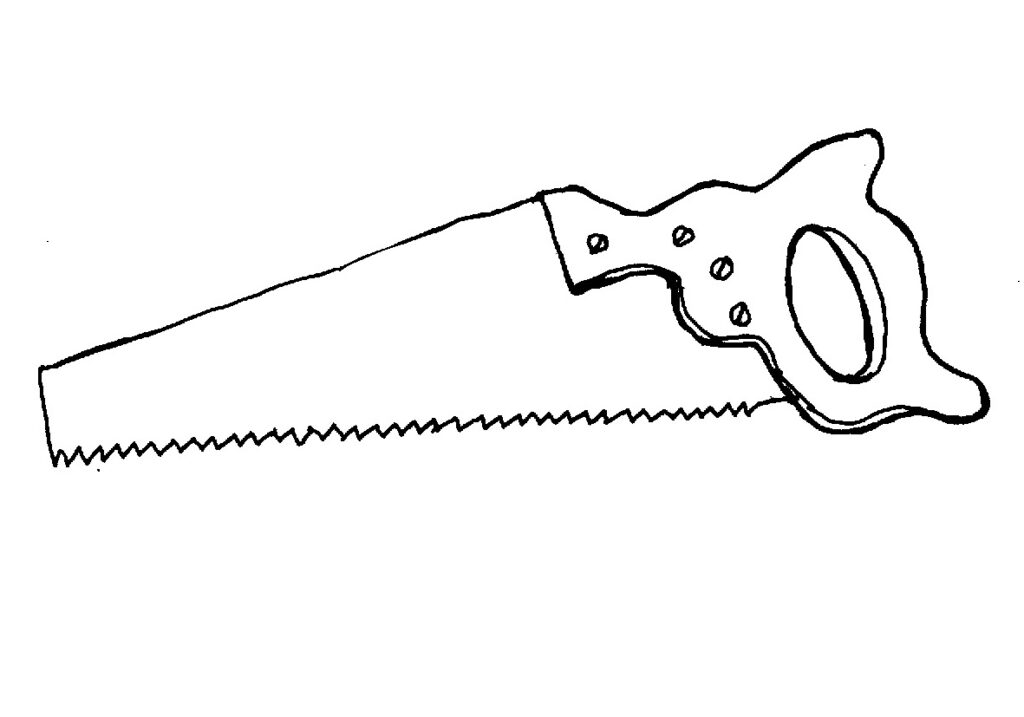

Because the Japanese saw cuts on the pull stroke, its blade is always in tension. The western push stroke crosscut saw typically has a large shaped handle allowing the carpenter to push the saw, and because it is in compression during the push stroke its blade must be much thicker.

The Japanese saw blade can be both thinner, and with less “set”, resulting in more precise cuts, and thinner still if the edges of the blade are made thinner than the centre.Since it is pulled, the blade naturally follows the handle, so it does not need a specially-shaped grip, and if the handle is longer it can be pulled with both hands for more powerful cutting. The blade and handle can also be made to fold like a pocket knife, or separated, with interchangeable blades.

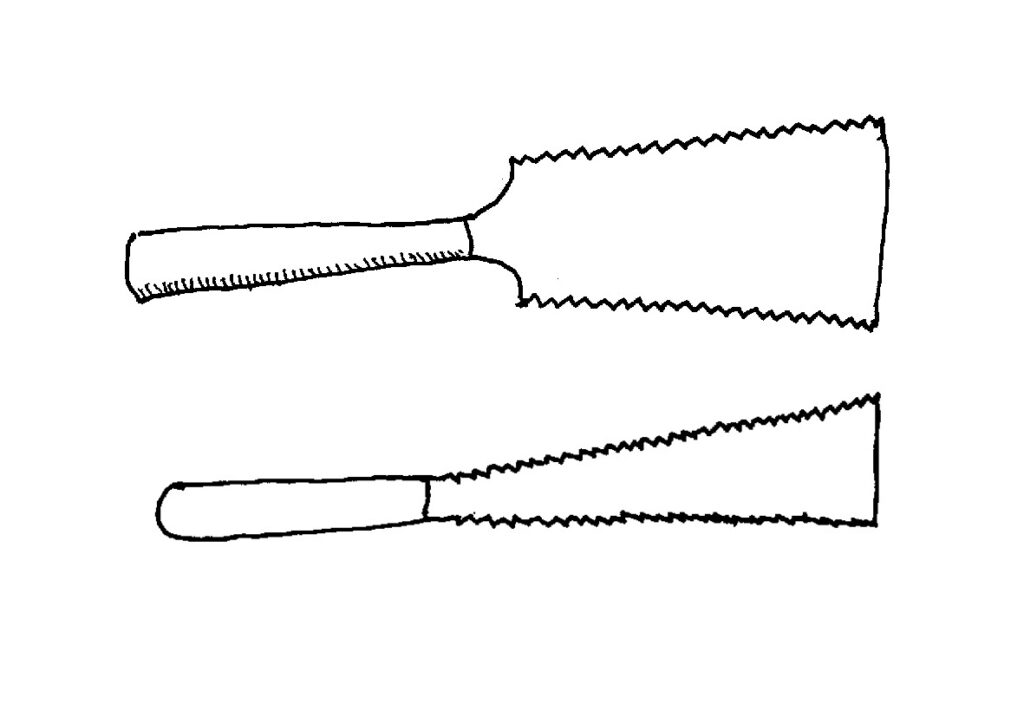

The common Nokogiri is a “Kataba”, with a one-sided blade.

A more distinctive Japanese saw is the “Ryoba” or double-blade saw, with cross-cut teeth on one edge and rip-cut teeth on the other.

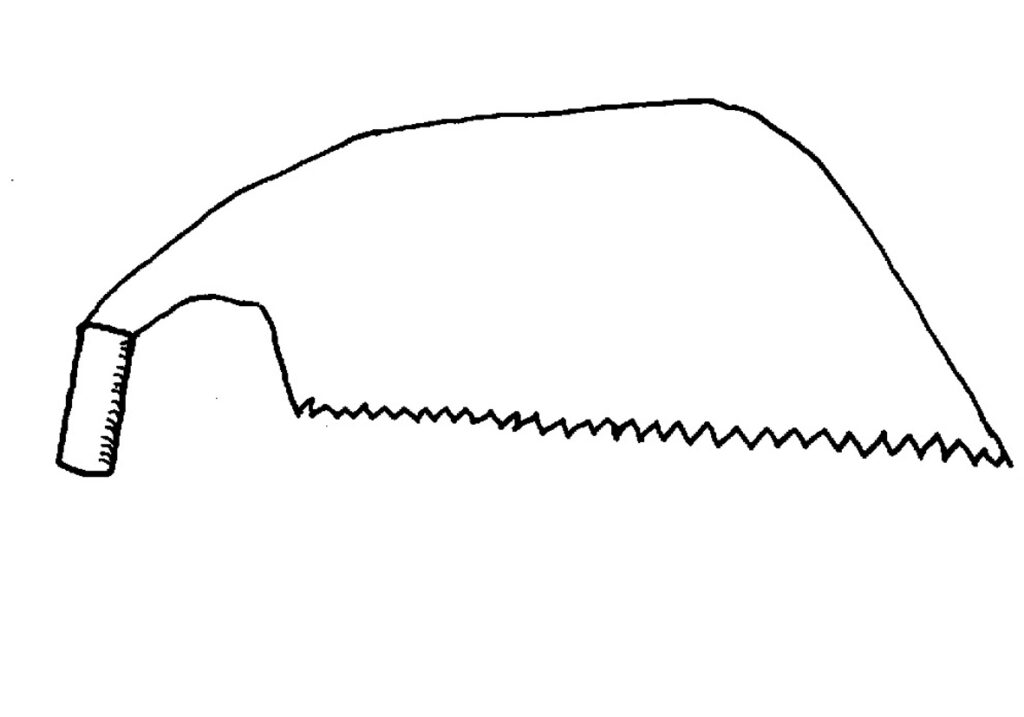

Perhaps even more distinctive is the large tree-cutting saw or “Ohga”, with its huge blade (typically 400 x 600 mm) and curved profile to place the handle on the axis of the teeth. These are often made with variable size teeth, smaller at the start of the cut and larger towards the end.

Many western carpenters have Japanese saws in their toolkit, and use them, especially for work where the pull-cut saw gives an advantage.

The beauty of Japanese carving and woodwork is the combination of unique artistry and the finest tools, such as the Nokogiri.