鑿 Nomi

The Japanese Chisel

Since our first ancestor split a stone and used it to sharpen a stick, humans have been making and using tools. Hammers, knives and axes can all be made with stone, bone or wood.

The availability of metals, especially iron and steel, allowed stronger and more sophisticated tools, such as swords, saws and chisels. The earliest known chisels were made of bronze by the ancient Egyptians, who developed all-metal versions for stone work and wood-handled chisels for greater precision.

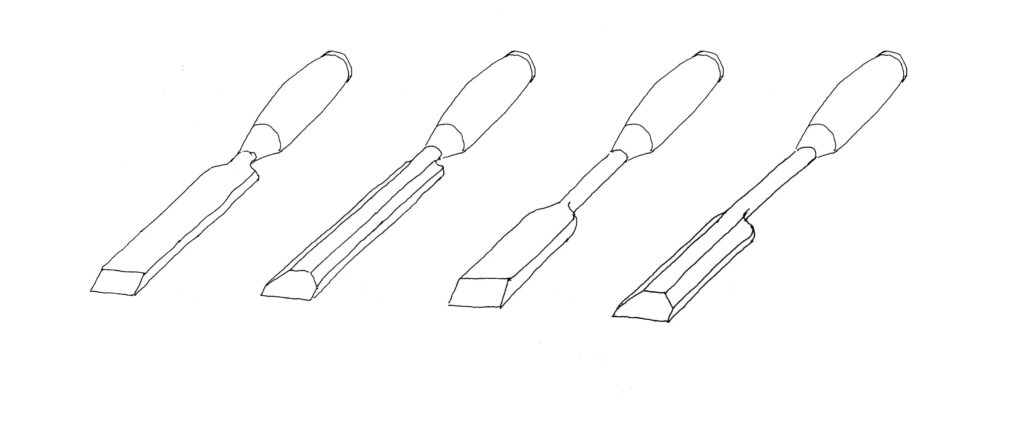

The Nomi (chisel) in Japan, used for woodwork, is similar to the western version: a cylindrical wooden handle, with a co-axial flat metal blade, sharpened at the end, The cutting blade is basically perpendicular to the handle, so they can be pushed or hammered. They are made in a variety of sizes, so a carpenter’s tool kit would include a set of chisels. The blades can be square-sided or bevel-edged, and specialist chisels can have curved or angled blades.

However, like the Kanna (Japanese plane), there are obvious differences. Like the kanna, these differences arise because its blade is much sharper. It is made using similar techniques to the manufacture of the Japanese sword, combining a blade of hard steel, which is brittle and would easily shatter in use, with a softer steel that absorbs impacts on the sharp blade.

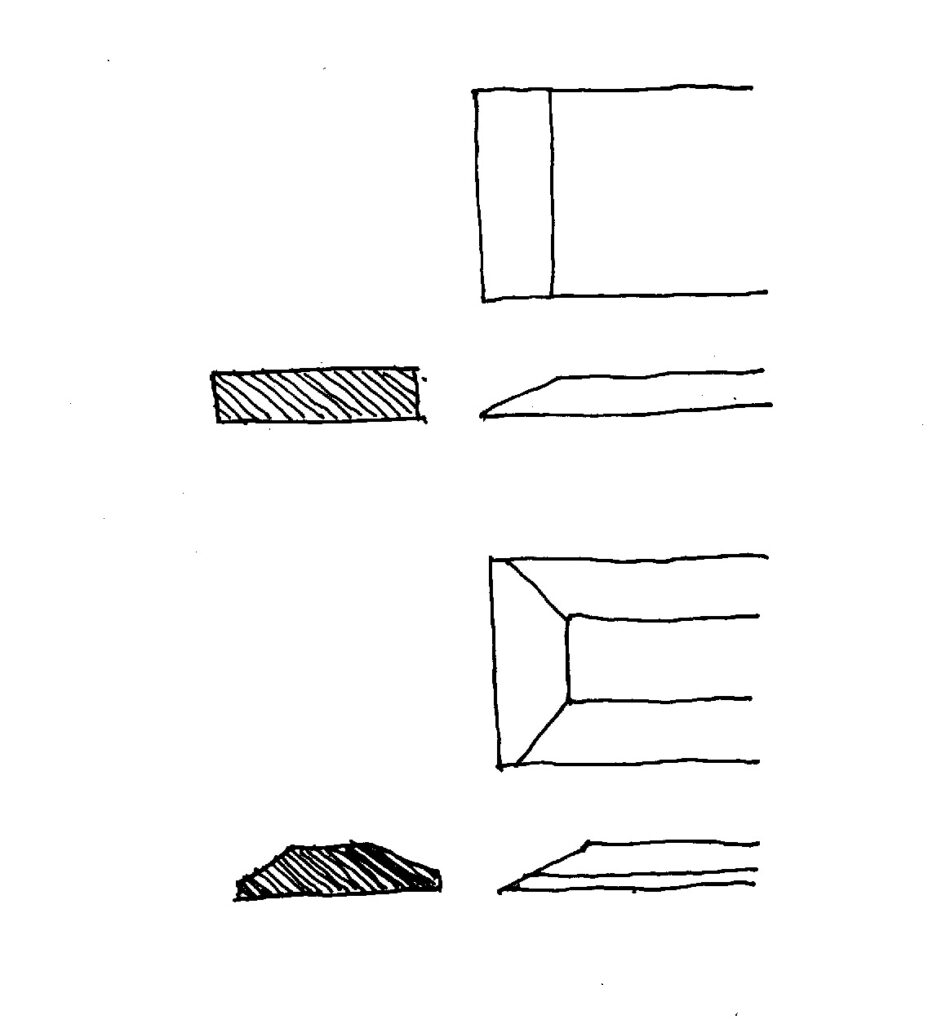

Straight Edge

Bevel Edge

Western Chisels Japanese Chisels

The most noticeable difference is that on the wider chisels, while the overall length is similar, the western chisel has a long thick blade for added strength, while the blade of the Japanese nomi can be shorter, with a longer shank and chamfered shoulders. The back of the wider blade is often dished or hollowed out, making the back easier to sharpen. Some wider chisels have multiple hollows.

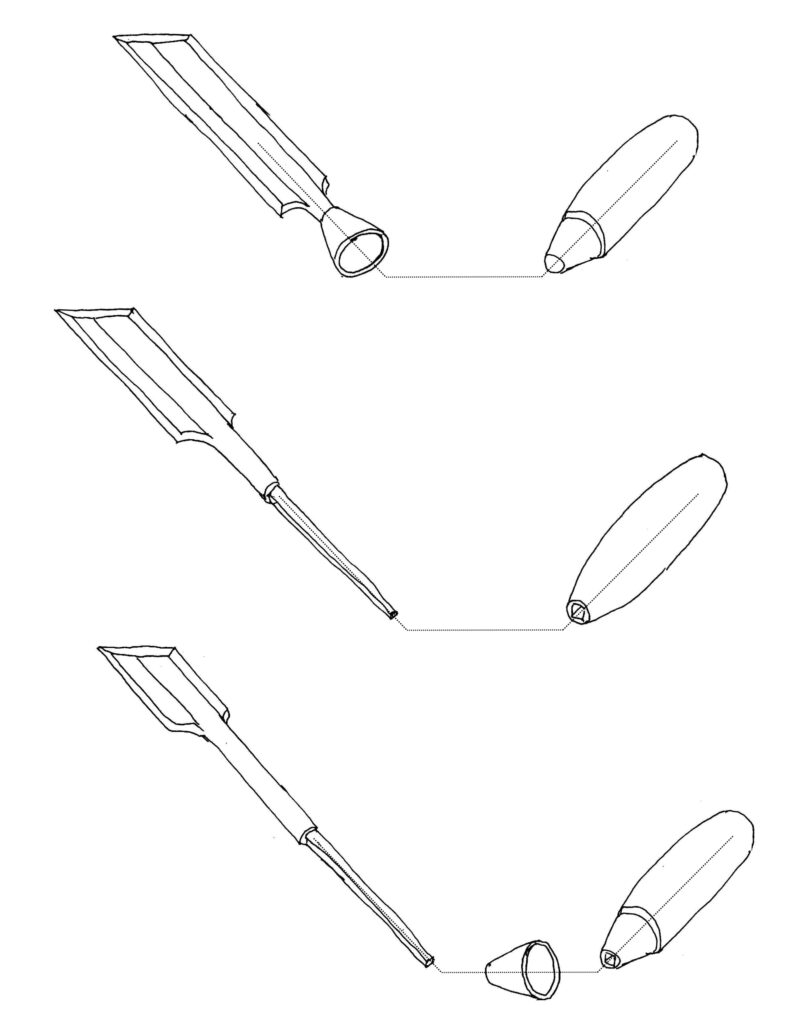

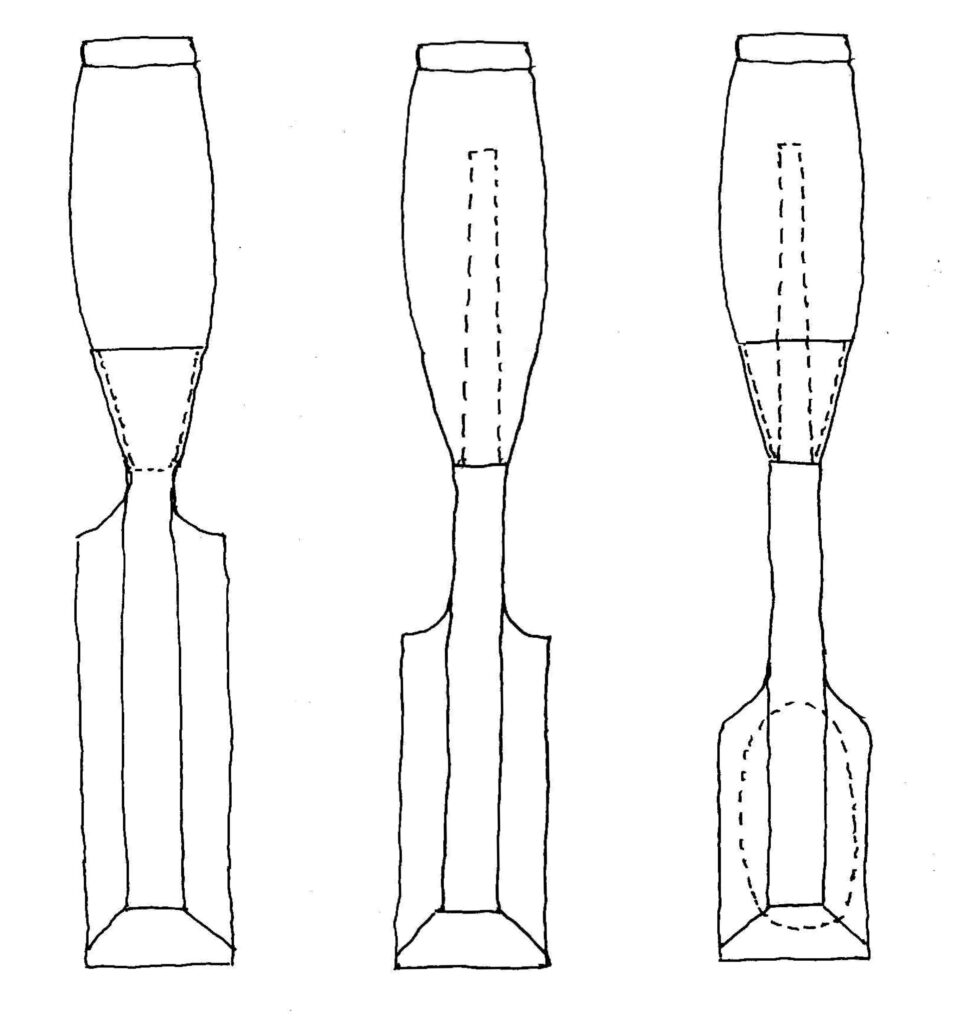

There are two basic methods of constructing wood-handled tools, socket, where the handle is inserted into a metal socket projecting from the blade, and tang, which is a metal piece projecting from the blade that fits into the handle. Both these types can have a ferrule around the lower end of the handle, High-quality Japanese chisels use a tang and a specially-shaped ferrule, which holds blade and handle together, and ensures the force of the hammer is transferred to the blade rather than risk splitting the handle. Western chisels may have a ferrule around the upper end of the handle. Japanese chisels always have this if the tool is intended to be hammered.

……………Blade & Handle Joints

dished (hollow) back

Socket ………………………. Tang ……………….. Tang & Ferrule

Nomi can be more precise, and its strength allows wider and longer versions. A typical western chisel set might range in widths from 6 – 25 mm, while a Japanese set could be 3 – 42 mm. Chisels used in Japan’s construction industry can be over 600mm long.

The precision, strength and durability of Japanese chisels are recognised worldwide, and many craftspeople in the west use them, especially for precision work such as the finer morticing and dovetailing used in joinery and cabinet-making.

The strength and durability of highest-quality blades can only be achieved by hand-working the steels, and the skills to do this have been lost outside of Japan. Tools made elsewhere use plain or pre-laminated steel alloys for mass-production.

The beauty of Japanese carving and wooden cabinetry is the combination of unique artistry and the finest tools, such as the Nomi derived from the Samurai Sword.